Improve VSM for Inventory Process in the Hospital Laboratory

- Frances Shbeeb

- Apr 24, 2022

- 1 min read

Updated: May 9, 2022

Managing the inventory for the laboratory is a key process in a hospital. This process can be costly and time consuming. The Supervisor starts the process by ordering supplies at a set frequency and ends with the technologist using the supply for patient testing. The process for inventory management depicted in Table A is commonly found in rapidly growing hospitals. Laboratories often use a non-automated method to order and receive supplies. Inventory rooms are usually disorganized with supplies not having a designated place.

The use of manual methods increase waste, reduce profit and decrease patient satisfaction. Valuable resources such as technologists could have been directed to do more productive tasks such as patient testing and result reporting. Wastes accumulate with unused or expired supplies. Profit is lost when technologists are paid overtime. Patient dissatisfaction increases when results are delayed. It is essential for laboratories in hospitals to have a more efficient way of managing their inventory.

Table A: Performance of Inventory Process

This table summarizes the performance, failing status and improvement suggestions of each step in the process.

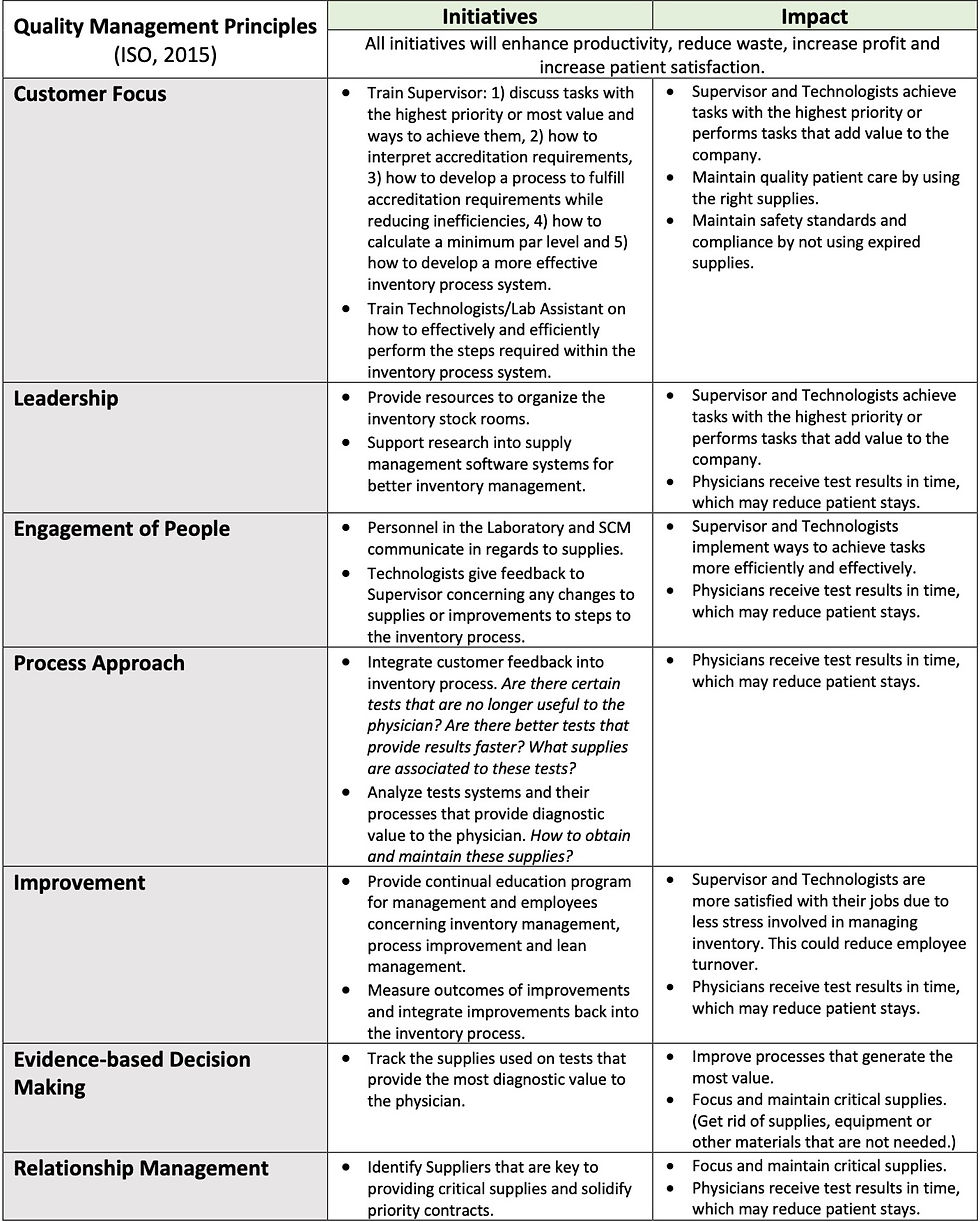

Table B: Initiatives

This table lists suggestions for each quality management principle and the potential impact of each suggestion.

Diagrams 1 and 2.

Diagram 1 maps the value stream of the manual inventory process whereas Diagram 2 maps the value stream of the automated inventory process. Significant reduction in delay time and waste can be realized with better management of the inventory process in a hospital laboratory.

REFERENCES Joint Commission (2017). Joint Commission enhances laboratory requirements. Retrieved on October 4, 2020 from https://www.jointcommission.org/-/media/enterprise/tjc/imported-resource-assets/documents/lab_joint_commission_enhances_reqspdf.pdf?db=web&hash=7D777F06CD2E9375764173077

Comments